Published on 2024-05-03

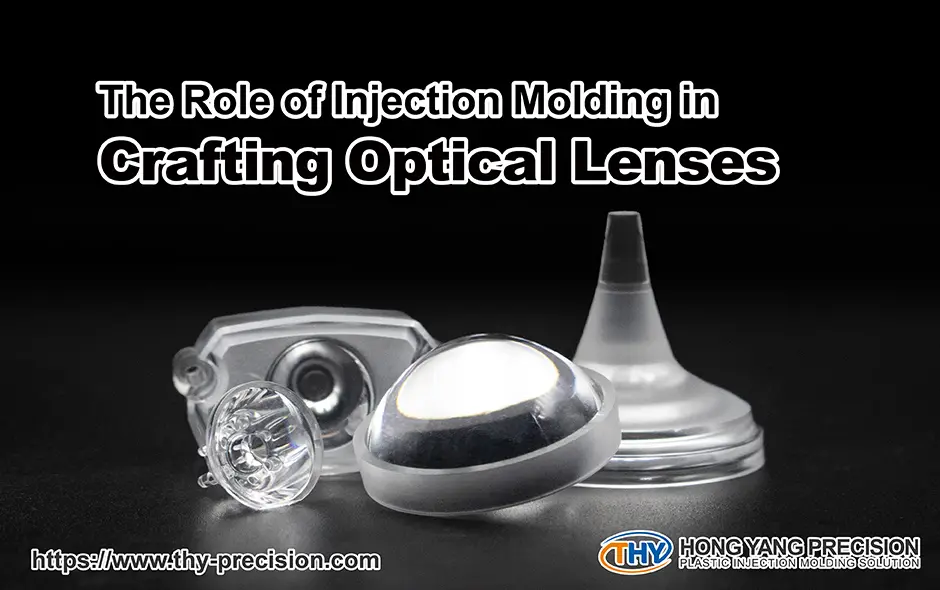

Smartphones, AR/VR headsets, and medical instruments — what do they all have in common? They all rely on high-precision optical components. However, as traditional glass optics struggle to meet the demands for smaller, lighter, and more cost-effective solutions, precision polymer optics have emerged as a powerful alternative.

Significantly lighter than glass, precision polymer optics are ideal for portable devices. Their versatile polymers can be molded into intricate shapes for innovative optical designs. Polymer optics can even integrate both optical and mechanical features into a single component, simplifying device assembly.

The key to achieving these benefits lies in injection molding, a process perfect for crafting high-precision optical lenses.

Table of Contents

The Unique Nature of Injection Molding for Optical Lenses

Precision injection molding is widely recognized for its efficiency in mass-producing complex components with stringent accuracy requirements.

Despite initial challenges, the technique is increasingly used for producing optical parts such as lenses, showcasing its versatility. When manufacturing optical lenses through precision injection molding, several critical factors must be addressed to ensure high-quality outcomes:

1. Residual Stress

High residual stress can adversely affect the optical properties of lenses, diminishing their performance. It’s crucial to minimize these stresses to maintain lens quality.

2. Repeatability

Achieving consistency in mass production, especially for products requiring precise accuracy and small-scale details, poses a significant challenge. Ensuring repeatability is essential for uniform quality.

3. Surface Contour Control

Beyond accuracy, the geometric consistency of the lenses is vital. Manufacturers must pay close attention to surface contour control to guarantee the lenses’ superior optical properties.

For comprehensive guidance on achieving perfection at every stage of the precision injection molding process, please consult the detailed design guidelines available at Essential Design Guidelines for Precision Injection Molding.

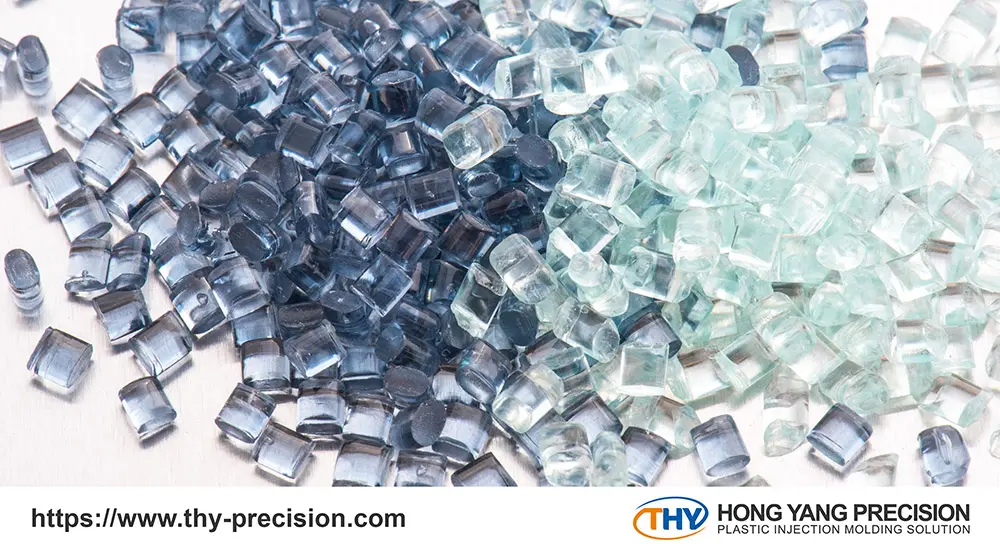

Principal of Optical Molding Materials

The selection of materials used in manufacturing is influenced by the optical purposes of final products and specific needs from clients. We need to carefully evaluate the properties of each thermoplastic prior to initiating the mold design process. Among these thermoplastic, polycarbonate, acrylic, and polystyrene are the mainstream materials employed in injection molding.

● Polycarbonate (PC)

Polycarbonate is a widely used material in precision injection molding, particularly valued for its exceptional optical properties. Not only is it a prevalent choice for injection molding, but its optical characteristics are also noteworthy. With a refractive index of approximately 1.59 and an 84% transmission of visible light alongside a 74.3% UV transmission rate.

● Acrylic (PMMA)

Acrylic is another material frequently utilized not just in injection molding, but also in various manufacturing processes like CNC lathe and milling, thanks to its superior mechanical properties. Additionally, acrylic offers unique optical characteristics. It boasts a refractive index of approximately 1.49 and an 83.1% transmission rate of visible light. Unlike polycarbonate, however, acrylic has a UV transmission rate of just 4.82%, effectively blocking nearly all UV light.

● Polystyrene (PS)

Polystyrene is ideally suited for precision molding, thanks to its low shrinkage which enables designers to craft intricate and detailed items. Similar to polycarbonate and acrylic, polystyrene also features a refractive index of 1.59 and an 88.4% transmission of visible light.

● Cyclic-olefin polymers (COPs)

COPs are celebrated for their superior optical properties, boasting an impressive 91.6% transmission of visible light and a refractive index of 1.53. Not only is COPs distinguished by its exceptional transmission of visible light, but it also features a minimal haze index of 1.78%, virtually eliminating haze in optical components.

● Cyclic-olefin copolymers (COCs)

COCs are versatile materials, suitable for a variety of applications including medical, optical, and electronics, due to their excellent properties. They are used in high-demand products such as optical films, lenses, and light guide panels. COCs stand out for their superior UV transmission compared to other materials like PC, PMMA, and PS, featuring a refractive index of 1.53 and a 90% transmission in the visible spectrum.

Mechanical Properties of Producing Lenses

In the field of precision injection molding, not only we need to consider the optical properties of materials, but also the mechanical properties of materials. The mechanical properties of materials play a vital role in producing optical lenses in injection molding.

● Thermal expansion

Thermal expansion of materials can interfere with the alignment between the guidepost and guide bush, impede the smooth movement of the slide core, or increase the dimensions of the core pins.

● Operating Temperature

The term “operating temperature” typically refers to two key temperatures in the context of materials: the melt temperature and the mold temperature. The melt temperature is the temperature at which plastic materials melt within the injection molding machine.

Setting this temperature correctly is crucial and depends on the specific type of plastic. It ensures that the material melts completely and flows properly. The mold temperature, on the other hand, relates to the surface temperature of the mold, controlled through a temperature control system.

Optimizing the mold temperature is necessary to align with the properties of the injection molding materials and the specifications of the final product. Different materials require varying melt and mold temperatures, as detailed in the table below:

| Melt Temperature | Mold Temperature | |

| Polycarbonate (PC) | 302 °C | 83.6 °C |

| Acrylic (PMMA) | 227 °C | 63.3 °C |

| Polystyrene (PS) | 217 °C | 37.1 °C |

| Cyclic-olefin polymer (COP) | 251 °C | 100 °C |

| Cyclic-olefin copolymer (COC) | 190 °C ~ 301°C | 40 °C ~ 170 °C |

● Water absorption

Water absorption increases the risk of molding defects and can compromise the tensile and impact strength of plastic products. Therefore, it is vital to adequately dry the material prior to production to sidestep these complications. Establishing the correct drying time and temperature is a key part of this preventive measure.

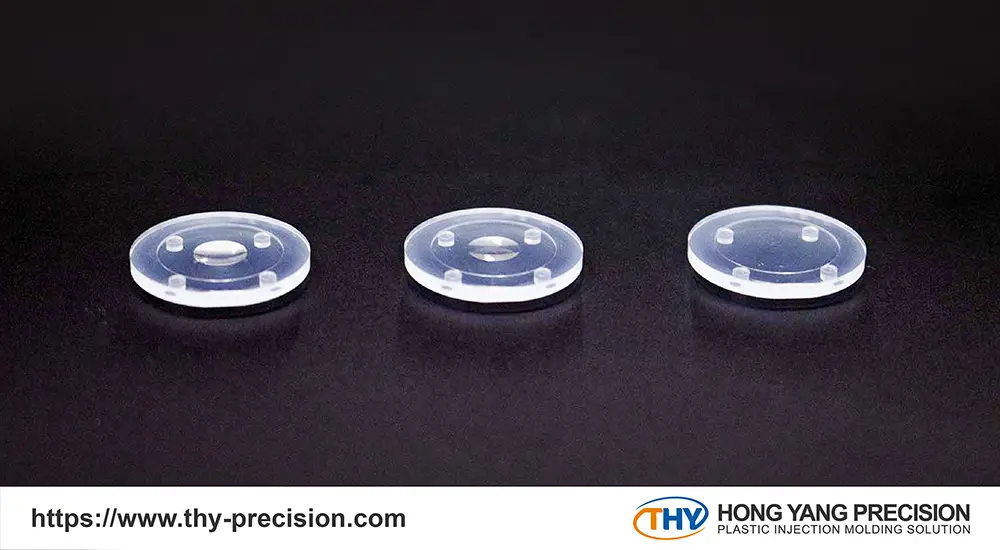

In addition to focusing on material properties, we prioritize our clients’ needs. Therefore, we manufacture optical parts in a cleanroom environment and meticulously control the dimensions of these parts to meet the stringent tolerance requirements of optical components. To guarantee the geometric precision of our products, we use optical profilometers to measure the finished products, ensuring that every part meets our clients’ specifications.

To navigate these hurdles and enhance the profitability of your product, we offer the expertise of seasoned R&D engineers who specialize in developing products tailored to exact client requirements.

THY is recognized as a leading injection molding producer of optical lenses that require precise tolerances (±0.05 mm), supported by our superior cleanrooms (Class 8 and Class 7) for clients demanding the highest standards to avoid contamination. Moreover, we are honored to uphold the ISO 9001 and ISO 13485 standards.

If you have any questions or encounter any design challenges, we encourage you to contact us without hesitation.