HOME / Plastic Injection Molded for Micro Electronics

Plastic Injection Molded for Micro Electronics

Why Use Plastic Injection Molded for Electronics?

Plastic injection molding is a manufacturing technique that transforms raw plastic materials, typically in granular or pellet form, into precise molded parts and products. Injection molded electronics involves melting the plastic and injecting it into custom-designed molds. Once cooled, the solidified plastic part is ejected and can either undergo further finishing or be used directly. This method is widely used in injection molded electronics manufacturing for six primary reasons:

Cost-Effective Production

One of the most significant advantages of injection molded electronics is its cost efficiency, particularly for high-volume manufacturing. Once the initial mold is created, the production cost per unit decreases significantly, making it an economical choice for mass production.

Design Flexibility

Injection molding supports intricate and complex designs, allowing manufacturers to produce detailed and customized components for injection molded electronics. This flexibility enables the creation of innovative products that meet specific requirements and functionalities.

Precision and Consistency

Ensures exact specifications and reliable performance, which are critical for injection molded electronics.

Durability and Strength

Injection molded parts used in electronics are known for their durability and strength. The materials used provide excellent mechanical properties, enhancing the longevity and reliability of electronic products.

Lightweight Construction

It reduces overall product weight, which is beneficial for automotive and aerospace applications.

Integration of Multiple Components

It minimizes assembly and potential failure points. This integration enhances the overall functionality and reliability of the electronic device.

Key Applications of Injection Molded Electronics

Injection molded electronics are used in a wide range of industries due to their versatility and the benefits they offer in creating durable and reliable electronic components. Some key application areas include:

1. Consumer Electronics:

Injection molded electronics components are essential in the production of smartphones, tablets, laptops, and other personal electronic devices. The ability to create intricate and lightweight parts contributes to the sleek and compact designs of modern gadgets.

2. Automotive Industry:

The automotive sector utilizes injection molded electronics for various applications, including dashboards, sensor housings, and control panels. The durability and precision of injection molded parts ensure reliable performance in the demanding automotive environment.

3. Medical Devices:

Injection molded electronics is widely used in the production of medical devices and equipment. The process allows for the creation of complex, sterile, and high-precision components used in diagnostic tools, monitoring devices, and surgical instruments.

4. Aerospace and Defense:

In the aerospace and defense industries, injection molded electronics are employed in applications requiring lightweight and durable components. Examples include avionics housings, connectors, and various electronic enclosures.

5. Telecommunications:

The telecommunications industry relies on injection molded electronics parts for the production of various devices such as routers, modems, and network equipment. The ability to produce intricate designs ensures optimal functionality and connectivity.

6. Industrial Equipment:

Injection molded electronics are used in industrial automation and machinery, where precision and reliability are essential. Components such as control panels, sensors, and connectors benefit from the robustness and consistency provided by injection molding.

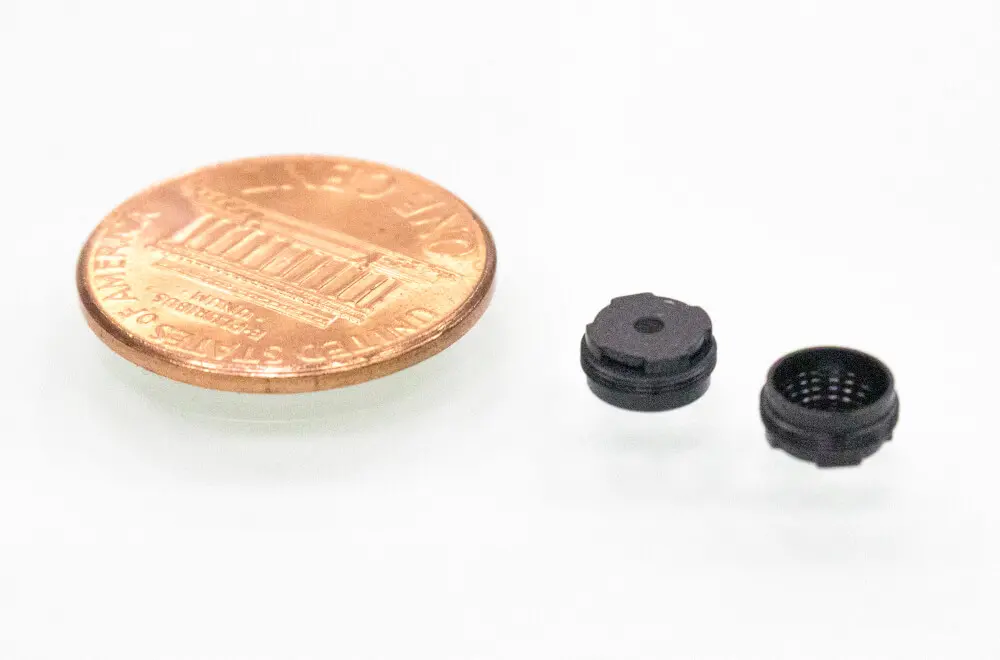

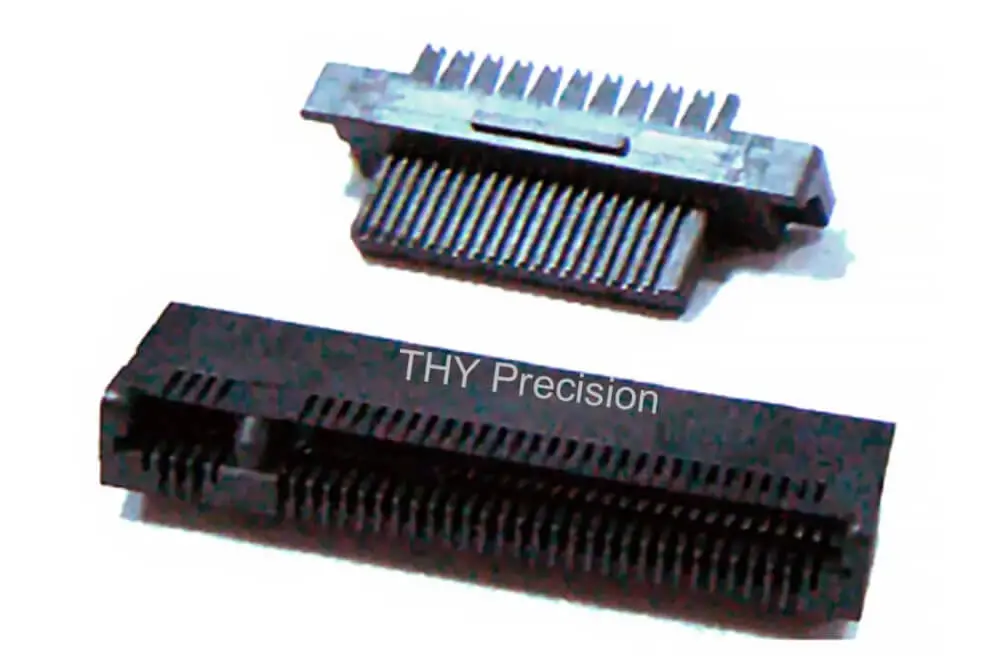

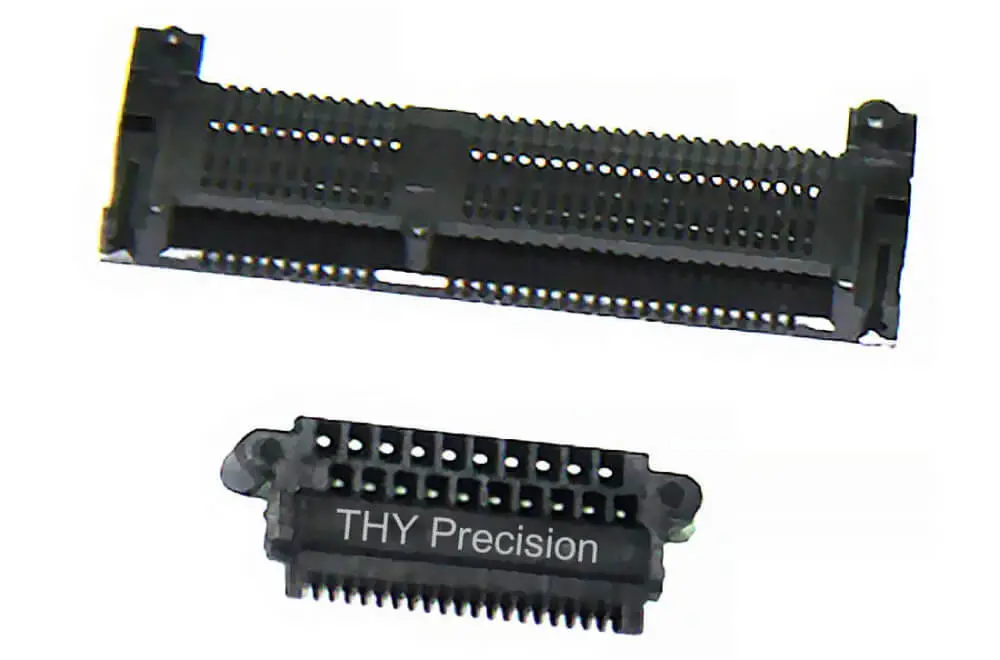

Custom Injection Molded for Complex Micro-Sized Electronic Components

Our commitment to excellence is reflected in our injection molded electronics, which are celebrated for their exceptional efficiency and extended functional life. We are dedicated to crafting micro-sized parts designed for consumer electronics and connectors, serving the needs of international clients who trust THY Precision products.

Our components are integrated into a wide range of devices, including digital cameras, cell phone cameras, webcams, camcorders, security cameras, and more. With their impeccable quality and outstanding performance, our products are highly esteemed in the quality-conscious market.

THY Precision is highly valued for our high precision electronic components manufacturing.

Why Trust THY Precision for Your Micro Electronics Molding Needs?

THY Precision stands out in the field of injection molded electronics, with a focus on microelectronics applications. Our expertise lies in the production of micro plastic components at the μm unit level. With a profound understanding of the industry, we specialize in developing and molding complex micro-sized electronic components that precisely meet our clients’ unique requirements. Our commitment to quality is backed by ISO 9001 and ISO 13485 certifications, ensuring that our processes adhere to the highest standards of quality and reliability.

Choose THY Precision for your injection molded electronics needs, and experience the unmatched quality and reliability that our micro-sized components bring to your electronic devices. Contact us today to start your project and see the difference our precision molding can make! Get a quote now!

Quality Control

Each Specific Design is developed in strict compliance with the prevailing industry standards and according to International Quality Standards.

Ultra Precision Molding

We use state-of-the-art machines, including All Electric Injection Molding, and high quality materials.

Insert Molding

Insert molding technology to meet customer requirements.

High Temperature Molding

Special heat-durable plastic that can withstand 260 °C furnace temperature (works with PCB operations).