Published on 2024-06-19

Selecting the right resin for injection molding is essential for creating high-quality finished products. To help you choose the best resin for your project, this article will cover the most commonly used plastic resins in injection molding.

Table of Contents

10 Common Plastic Resins for Injection Molding

Prior to determining the plastic resins for injection molding, it’s advised to understand the concept of thermoplastics and thermosetting plastics as polymers are melted under high pressure during the injection molding process.

Thermoplastics and thermosetting plastics are two unique categories of polymers that respond differently to heat. Thermoplastics are versatile, allowing for repeated heating, cooling, and reshaping without any change in their chemical composition. On the other hand, thermosetting plastics experience a permanent chemical transformation when heated, creating irreversible bonds that fix their shape for good.

In common practice, thermoplastics are ideal materials for injection molding due to their recyclability and versatility in forming complex shapes and designs. Their adaptability makes them a preferred choice in various industries.

At THY, we excel in manufacturing products using thermoplastics, and below are some of the common thermoplastics utilized in injection molding:

1. Polypropylene (PP)

Polypropylene (PP) is the most widely used resin for injection molding due to its effectiveness in producing high-precision, size-specific products, such as hydrophobic intraocular lens (IOL) discs for treating eye diseases. Utilizing medical-grade PP allows for the efficient mass production of various size-specific products, providing cost-effective solutions

2. Polycarbonate (PC)

Polycarbonate is a versatile thermoplastic, often selected for its optical clarity and toughness. Due to these characteristics, polycarbonate resins are frequently used as a lightweight alternative to glass and are ideal for applications requiring high-impact resistance. If your project involves optical lenses, we also talk about what needs to be considered when designing optical lenses in this in-depth discussion.

Injection molding offers the greatest flexibility when working with polycarbonate (PC). This method allows for varied shapes, production scales, and enhanced mechanical and optical properties, making it ideal for high-volume production at a low cost per unit.

3. Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile imparts heat and chemical resistance to the final product, butadiene boosts impact resistance, and styrene adds strength and a glossy finish. Commonly used in plastic toys, ABS makes them affordable for most consumers.

4. Polyethylene (PE) (classified into LDPE/HDPE)

Variations in the density of Polyethylene (PE) significantly influence its physical properties and practical applications. Types of PE like LDPE, which are lower in density, display less crystallinity, thereby enhancing their flexibility. Conversely, HDPEs are higher in density, demonstrating greater crystallinity and stiffness.

Typically, polyethylene is known for being lightweight, chemically resistant, and an effective electrical insulator in the industry. The strength and stiffness of PE vary by type, with injection molded variants frequently used in applications requiring resilience to stress or strain.

When selecting the appropriate type of polyethylene, designers must weigh potential trade-offs, as increased stiffness often correlates with higher brittleness. Additionally, different PE types offer varying degrees of resistance to specific chemicals or sunlight.

5. Polymethyl Methacrylate (PMMA)

PMMA, or polymethyl methacrylate, boasts impressive physical properties such as high tensile strength, significant flexural strength, and glass-like transparency, making it a popular substitute for glass. However, PMMA is more brittle than PC (polycarbonate), which means it is more prone to cracking or breaking under stress.

This resemblance to glass underpins its widespread use as a cost-effective and more resilient alternative to traditional glass. It’s particularly favored in the bio-industry for applications like cuvettes, where its transparency allows for economical and frequent transmission measurements.

6. Polystyrene (PS)

Polystyrene(PS) is the preferred material for manufacturing items like cases, disposable spoons, and cups, largely due to its adaptability to the injection molding process.

This method is widely favored for producing many such products. Polystyrene stands out from other resins because it can be either a thermoplastic or a thermoset, depending on its polymeric structure. This versatility allows it to be molded into various forms and ensures it meets specific needs across different applications.

7. Liquid Crystal Polymer (LCP)

Liquid Crystal Polymer (LCP) plastics are renowned for their exceptional resistance to high temperatures, impressive mechanical strength, and superb dimensional stability. They also boast high dielectric strength and a low coefficient of thermal expansion. Due to these outstanding properties, LCP is extensively utilized in the medical and electrical fields.

8. Polyoxymethylene (POM)

Polyoxymethylene (POM) is known for its strong physical, mechanical, and chemical properties, especially its excellent friction resistance.

It holds the position as the third most utilized general engineering plastic. This makes it ideal for the production of wear-resistant components, transmission parts, and various parts used in chemical and instrumentation applications.

9. Polyamide/Nylon (PA)

Polyamide/Nylon (PA), a synthetic thermoplastic polymer composed of non-natural molecules, is extensively used in injection molding due to its versatility, flexibility, and durability, offering a more affordable alternative to materials.

It boasts a high melting point, making it suitable for replacing metal in harsh environments. Additionally, its low friction contributes to a slow wear rate, allowing it to function well alongside metal components and surfaces. Polyamide also exhibits significant chemical resistance, which is crucial in industries such as the medical sector where devices and equipment frequently contact hazardous chemicals. Moreover, it possesses high tensile strength, giving it superior resistance to fatigue from bending and flexure compared to most thermoplastics.

10. Polybutylene terephthalate (PBT)

Polybutylene terephthalate (PBT) provides numerous benefits for injection molding, such as UV resistance, heat resistance, and significant dielectric strength.

Here’s a table summarizing the key characteristics and applications of each resin for injection molding mentioned in the article:

| Resins for Injection Molding | Key Characteristics | Common Applications |

|---|---|---|

| Polypropylene (PP) | Toughness, flexible, outstanding heat and chemical resistance | Medical treatments (Intraocular Lens Discs) |

| Polycarbonate (PC) | Optical clarity, toughness, flexible in production | Varied high-volume products |

| Acrylonitrile Butadiene Styrene (ABS) | Heat and chemical resistance, impact resistance, glossy finish | Plastic toys |

| Polyethylene (PE) | Lightweight, chemically resistant, varies in density (LDPE, HDPE) | Resilient applications |

| Polymethyl Methacrylate (PMMA) | High tensile and flexural strength, glass-like transparency | Bio-industry (cuvettes), glass substitute |

| Polystyrene (PS) | Adaptable to injection molding, versatile in forms | Cases, disposable spoons, cups |

| Liquid Crystal Polymer (LCP) | High-temperature, resistance, mechanical strength | Medical and electrical |

| Polyoxymethylene (POM) | Robust physical, mechanical, chemical properties, friction resistance | Wear-resistant components, transmission parts |

| Polyamide/Nylon (PA) | Versatility, durability, high melting point | Replaces metal in harsh environments |

| Polybutylene terephthalate (PBT) | Heat resistance, dielectric strength | Electrical and electronic insulation parts |

How to Select the Best Resin for Plastic Injection Molding?

Choosing the appropriate plastic resin for injection molding requires a comprehensive understanding of the final product. Consider the following questions to identify the most suitable resin materials for your needs:

1. What is the intended purpose of the final part?

- Clearly define the physical requirements of the part, such as potential stressors, environmental conditions,and chemical exposure.

- Assess the necessary strength of the part.

- Determine whether the part needs to be flexible or rigid.

- Evaluate if the part must withstand unusual levels of pressure or weight.

- Consider the part’s exposure to chemicals or other elements.

- Ensure the part can endure extreme temperatures or harsh environmental conditions.

- Estimate the part’s life expectancy.

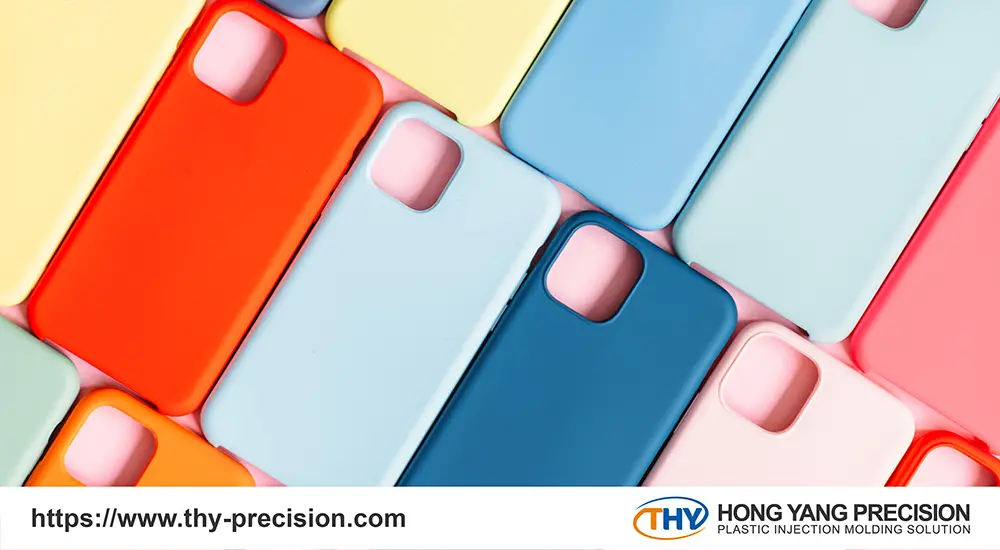

2. Are there special aesthetic considerations?

- Select a material that meets the desired color, transparency, texture, and surface treatments.

- Check if there is an existing color that needs to be matched.

- Consider whether embossing is necessary.

Last but not least, In addition to selecting the right materials for your projects, gaining a comprehensive understanding of design guidelines for injection molding can serve as a precaution against failures and defects.

Struggling to Find the Resin? Let Experts Help

If you’re having difficulty selecting the appropriate plastic resin for your injection molding project, don’t be discouraged. Consulting with a material selection expert from THY Precision can help you make informed decisions and bring your ideas to life efficiently and within budget.

THY Precision will:

- Assist you in choosing from a variety of plastic material options.

- Provide guidance on evaluating these materials based on your specific application needs.

- Employ best practices to ensure your product reaches the market successfully.

Additionally, if you need specific color requirements for your plastic products, we can accommodate that too! Clients are welcome to specify the PANTONE color number, and THY Precision will find the appropriate color powder or color masterbatch for accurate color matching. If the raw material needs to be dyed, please note that the base color must be white or a transparent base color that can be dyed.

Interested in our support? Contact us today, and our team will gladly offer expert advice.

THY Precision is backed by experts experienced in precision injection molding. Beyond our skilled team, we are renowned for manufacturing parts with all-electric injection machines that are able to meet your tolerance requirements. For clients looking for a cleanroom facility, our factory is strictly certified with ISO Standards for medical devices, namely ISO 13485, class 7 and class 8 cleanrooms.